By Jenn Patterson, MLitt

2/13/25

It’s not easy being green, but researchers at New York’s Fashion Institute of Technology, Science, and Math have found a way to make talking about the efficiency of manufacturing processes a little easier.

Amid what the United Nations calls the “defining crisis of our time,” scientists, governments, industry, consumers, and other stakeholders want new ideas, innovative and scalable tools, and sustainable solutions to save the planet.

Employing three commonly used circularity and efficiency measures in a novel way, the authors of a recent report in Sustainability & Circularity NOW have a promising, “upcycled” set of tools that may impact the scientific community at large. This new holistic approach offers quantifiable results and a simpler means for scientists to identify environmental efficiencies and inefficiencies in the processes they examine.

The unedited manuscript, accepted for publication in the first open-access peer-reviewed journal to address sustainability and Earth’s vulnerability to environmental threats, argues that collecting data related to recycled content, process mass intensity, and e-factors (environmental factors), among others, is essential to a meaningful discussion about sourcing, transformation, and reactant disposal in the design and development of processes and products. The best part? The researchers’ method is scalable and not limited by disciplinary boundaries.

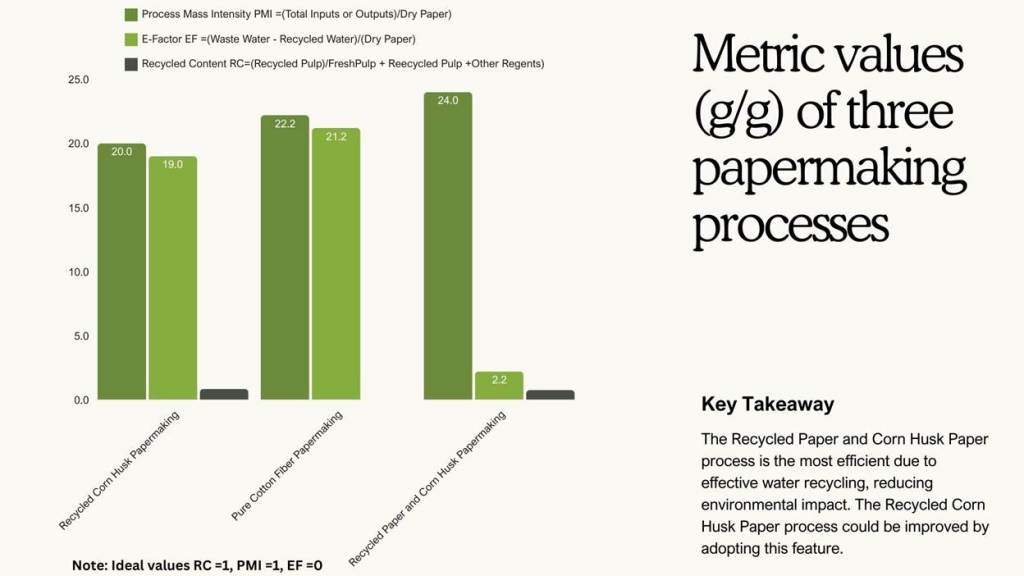

To illustrate their approach, the research team conducted a case study analyzing the efficiency and sustainability of three different craft papermaking techniques. The study offers a snapshot of various ways of transforming raw materials into paper, from pure cotton fiber to a mix of recycled paper and corn husk paper to just recycled corn husk paper. The case study’s key takeaway, shown in the figure below, is that the procedures for making recycled corn husk paper are more efficient than the others. The researchers attribute this to that process’s use of recycled water and assert that the recycled corn husk paper process would readily benefit from adopting a similar process.

The larger value of the study is in the methodology it establishes. The straightforward combination of well-known metrics offers a resourceful means for successfully evaluating and quantifying data in a discipline-agnostic way. The authors caution that even though “all procedures benefit from a low process mass intensity and low E-Factor, the best process does not yet exist. It can be fashioned with conclusions drawn when evaluating the metrics of e-factor, recycled content, and process mass efficiency.” In pulling together these metrics in an easy-to-use and broadly applicable way, they’ve added one more weapon to the collective fight to combat climate change and promote sustainability.